Pure, Uniform, Robust

At VNR, Quality is always the result of focused, consistent & intelligent effort

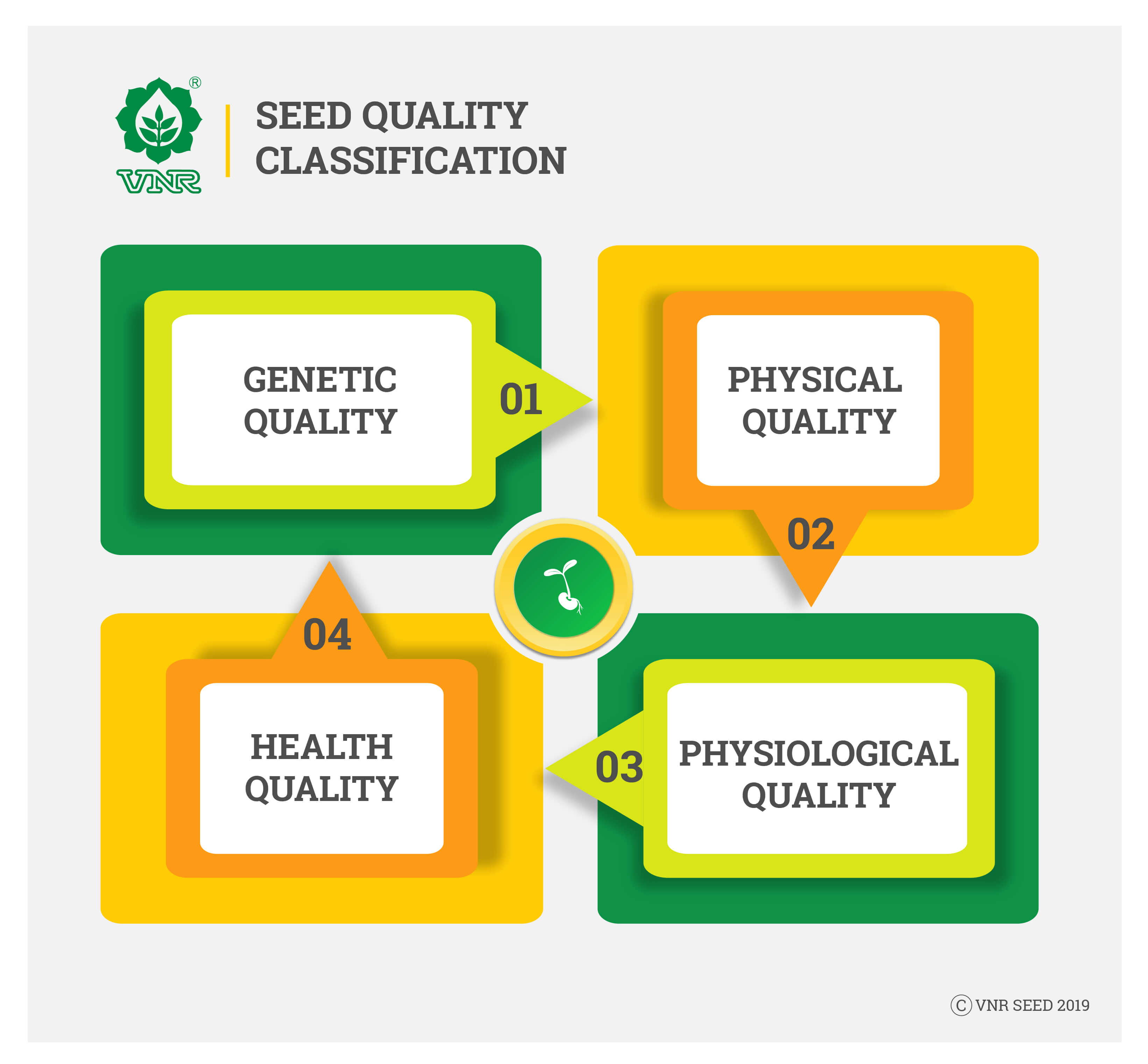

Seed is Mother Nature’s precious gift to mankind and as man depends on the seed for his survival, he bears the onus of the seed’s well being. Seed is the fundamental input in agriculture and a farmer’s entire crop depends upon the quality of the seed. Therefore, it is essential to plant good quality seed. Seed quality is a concept made up of several attributes. It is the responsibility of QA team to precisely assesses and preserve quality of seed. Quality attributes are mainly categorized as: True to type, high in germination and with high vigour, physically pure, free from seed borne diseases and chemically treated. It is a highly technical and exacting task. These attributes are ascribed to a seed lot and not to a individual seed.

Quality as perceived by a farmer is, when he opens the pack and examines a sample set, spread on his palms and forms an opinion based on seed size, shape, colour, build and uniformity. This is confirmed by the germination, response to cultivation practices and even growth pattern observed in the fields. It is to fulfill these requirements that the quality department strives and adopts the best available technologies.

Quality Assurance Objectives

Quality assurance (QA) team conducts periodical audit during various stages of seed production at production fields. They follow standard operating procedures for inspection, monitoring and testing during production, processing and storage of seed. The objective of providing quality seed to farmer is achieved by constant monitoring, testing and tailoring processes of production, processing, handling, storage and treatments at relevant and critical times during the lifecycle of seed lot. Auxiliary procedures like drying and fumigation at pre-determined intervals prevent deterioration of quality.

Farmers put in immense efforts and work with vagaries of environmental challenges during seed production. He takes utmost care in field to preserve every single seed and hands it over. VNR understands the true value of every single seed produced and quality department ensures that every individual seed is handled delicately and endeavors to minimize the wastage of seed.

Quality assurance ensures that critical organizational resources like manpower, facilities and infrastructure are optimally utilized and protected against wasteful usage. Every such measure ushers in value and garners self respect and pride in being of service to humanity and environment simultaneously.

To fulfill deliverables of the highest order, QA team has readiness to upgrade and seek to implement the latest available and feasible technologies. The aim for technology adoption, is to go all out and get the best effective/accurate result in short time span.

Quality assurance department at VNR continuously strives for competency development of its team and train them in technological advances, skill development and error proofing. These develop the personnel into competent profession who deliver perfect quality of seed owing to a zero tolerance approach.

To determine the genuineness of cultivar prescribed standards and protocols as per ISTA (International Seed Testing Association) are being practiced and adopted. ISTA protocols are being followed in all the tests.

VNR adheres to the stipulates of the law of the land and it totally compliant. All the processes implemented are as per the provision and rules prescribed in The Seed Act 1966, The Seeds (Control) Order 1983, Quality assurance guidelines as per National Seeds Policy 2002, Seed analysis & seed testing guidelines of Seed Bill 2004 and other applicable regulations. In fact, VNR shall be ready for future compliance requirements as and when they are enforced.

Field Quality Inspection & Monitoring

Periodical independent audit is conducted by quality team at critical stages – before flowering, during flowering and post flowering. Important parameters inspected are:

- Isolation distance: The problem of degradation in genetic purity due to outside influence such as foreign pollen, out cross, disease, dissemination etc. is overcome by providing adequate isolation distances (which is specific to each crop) and beyond which flow of viable pollen is not generally apprehended.

- Parentage purity check: Seed source is checked to ensure use of high quality true to type seed for sowing of seed crops. It also helps in identification of off types.

- Plant protection measures for crop health: Plant protection measures are followed to protect the seed crop from the attack of various insects and disease. Field quality team recommend technical input on plant protection measures based on diagnosis conducted during inspection visits which helps to raise a healthy crop.

- Roguing: Inspection of roguing cycle is monitored which is essential to avoid genetic contamination and transmission of seed borne diseases. Roguing involves removal of off type (phenotypically different) plant from the field of production variety.

- Crop nicking: Nicking which is the synchronous flowering of male and female parents. When there is a good match it ensures better yield of optimal quality. When there is a mismatch yield as well as genetic purity is likely to suffer. Asynchronous flowering of the designate parents could result in the female parent getting pollinated by alien undesirable pollen and this needs to be monitored especially in the context of time isolation.

- Yield estimation: Field inspection conducted during various stages of production, field quality team is aware of prevailing field conditions and they provide an independent estimation of yield which is useful for planning of subsequent functions like processing and marketing.

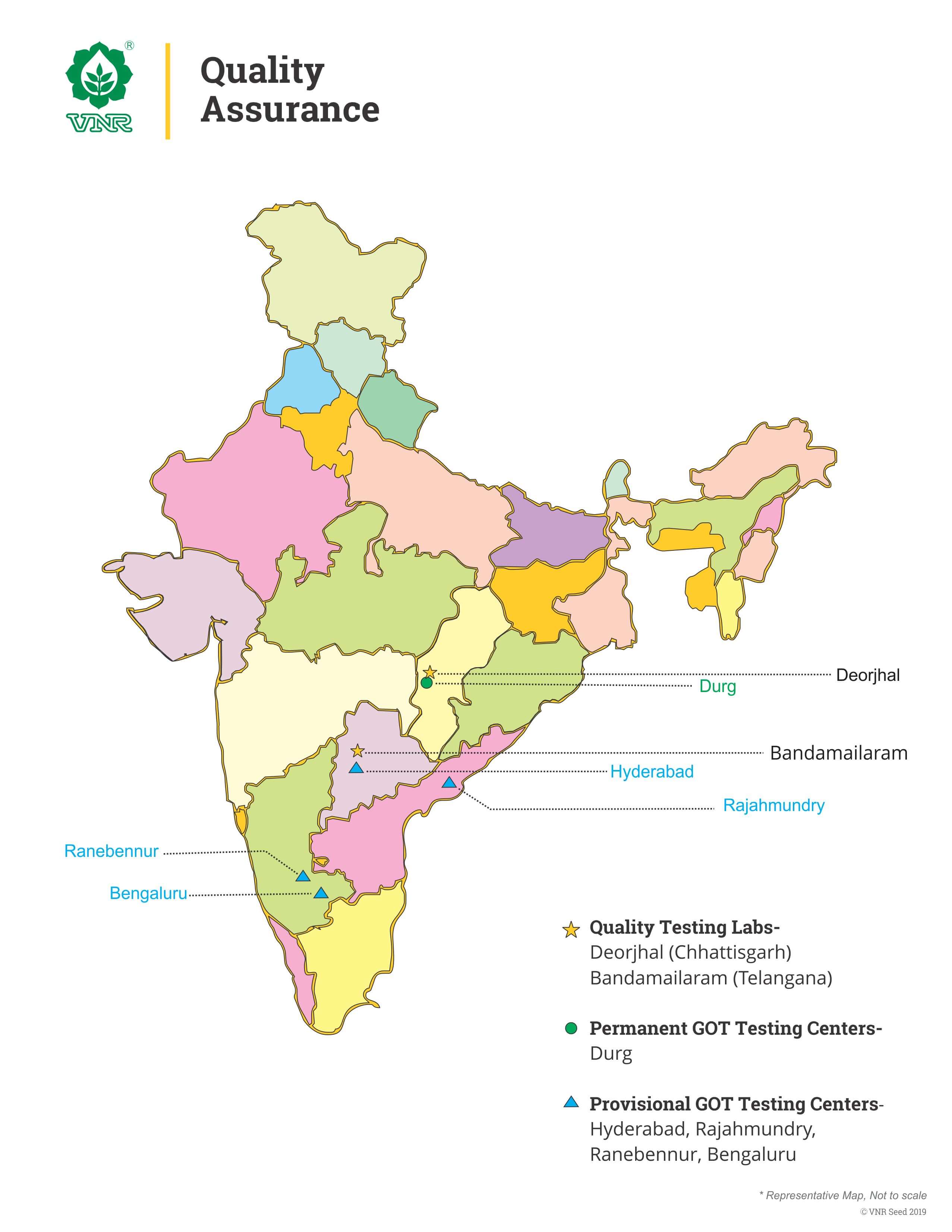

- GOT recommendation: GOT recommendation is an activity to handle lots with suspected issues separately. All seed lots are subject to Grow out Test for ascertaining genetic purity. Lots that get recommended for GOT are rigorously tested with higher sample size. Such lots are handled individually and stored separately till they are cleared for further processing.

- Seed dispatch or rejection: Only approved seed lots are dispatched to processing plant and any lots rejected due to adverse condition are suitably disposed off by burning or other destructive modes.

Audit and recommendation given by field quality team, when timely implemented ensures good harvest with optimum quality.

Seed Sampling

The seed lots arrived at processing plant are subjected to comprehensive sampling from every bag so to create a representative sample. Samples taken from seed lots are required to be reduced to obtain working samples for carrying out various tests. There are various types of mixing; dividing methods available for obtaining working samples like mechanical dividing, random cup method etc.

A Guard sample is also created from this working sample and is kept in separate guard sample repository to be referred, in case further investigation or test is required.

Physical Purity Test

It is desirable to sow seeds which are free from weed-seed, seeds of other crops, other distinguishable variety (ODV) and inert matter like straw, broken seed, stone and soil particles. Seed with high physical purity when grown by farmers gives better result. Physical purity test is conducted on every lot at every stage to ascertain percentage of impurities present in seed lot. Based on physical purity assessment, QA recommends further operations to processing department.

Moisture Test

Moisture content in seed impacts both storability and processing. Moisture is the most important factor influencing loss of viability during storage of seed. Dried seed results in better storability, even at the ambient temperature. Seed moisture content is also important for seed processing. Seeds are normally processed at a determined level of moisture to avoid damage to the living embryo. Seed gets damaged, when the moisture content is higher or less than the desired optimum level.

Germination, Vigor & Vitality Test

Germination percentage indicates the potential of seeds for developing and establishing into seedlings. Germination percentage is tested on pure seed fraction. The combination of pure seed and germination capacity is called pure live seed content and is calculated by its formula. Germination test is conducted with multiple replications where each replication carries 25/ 50 / 100 seed and is done in various media viz. paper, soil and sand. Vigour is represented by degree of aliveness. It indicates the ability of seed to emerge in varying environments of fields. To measure vigour, Seed samples are tested in stress conditions.

Genetic Purity Test

Important to have varietal purity because yield potential of a variety can be realized by farmers only if the variety is genetically pure. Varietal purity is assessed by conventional in-field ‘Grow Out Test (GOT)’ which is a time-consuming test and by biotech lab test using ‘DNA Molecular Marker Technology’. At VNR, each and every lot of seed is tested for Genetic purity.

Seed Health

Seed lots free of infestations and diseases are termed healthy. Healthy seed lots translate to a full stand on the field which is a very desirable attribute of a seed lot. Seed borne diseases are preventable by measures of good agronomic practices and appropriate chemical controls. Proper handling and treatments keep infestations under control.

Size and Uniformity

Uniformity of size is important for visual appeal and helps in mechanized sowing and precision planting. Shriveled, under size and oversize seeds are removed during cleaning and processing. Uniformity in size not only helps in mechanical planting but also ensures uniform germination /field emergence and gives good impression to buyer.

Inspection & Monitoring during Processing, Storage & Transportation

At every stage, VNR QA draw samples and if any deviations are observed in quality parameters than appropriate corrective measures are taken.

Processing: QA along with processing team ensures that seed processing is undertaken at appropriate moisture level, processing equipment is duly calibrated and right size screen used to pack the best quality seed.

Storage: Appropriate storage conditions are suggested and monitored by QA team like storage temperature, moisture level, staking height, type of packing material to maintain the best level of viability and vigor of seed.

Transportation: Depending upon destination and prevailing weather condition and season, QA team suggest the appropriate measures to be taken for transportation of seed. QA team ensures that suggested measures are duly followed during transportation to maintain the viability and vigor of the seed.

Data Analysis

Seed quality data is collected, compiled, processed and analyzed through an indigenously custom-built software application—Seedtrac. This integrated supply chain management application platform helps in keeping track of lot antecedents from seed production to dispatch and captures every quality footprints giving a complete view of lot biography. This qualified data input helps QA team in decision making for result declaration, reporting, retrieval and archival.

“We ensure and assure, every lot of seed reaching the farmer meets all our stringent quality standards.”